Exploring Expanded Metal Mesh Surface Treatment: Galvanizing, Coating and Corrosion Resistant Technology

As a common construction and decoration material, Expanded Metal Mesh's surface treatment is essential to protect its beauty and durability. In this article, we'll take an in-depth look at surface treatments for Expanded Metal Mesh, including galvanizing, coating.

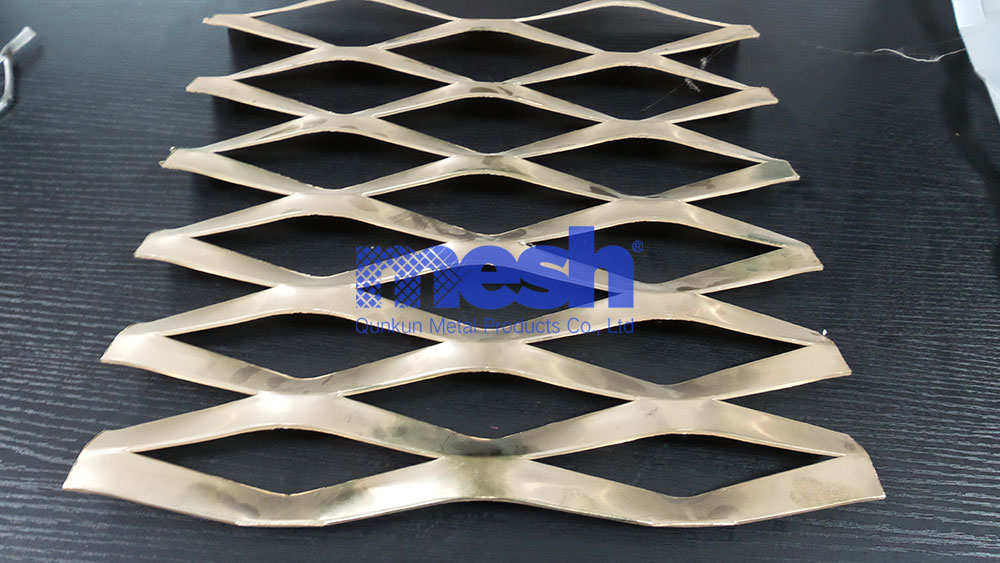

Galvanized: a solid line of defense against corrosion

Galvanizing is a common surface treatment that prevents corrosion by forming a protective layer of zinc on metal surfaces. Galvanized Expanded Metal Mesh performs well in sunlight, rain and air due to zinc's excellent resistance to oxidation and corrosion. In addition, the galvanized surface can also enhance the hardness of the metal mesh and prolong its service life.

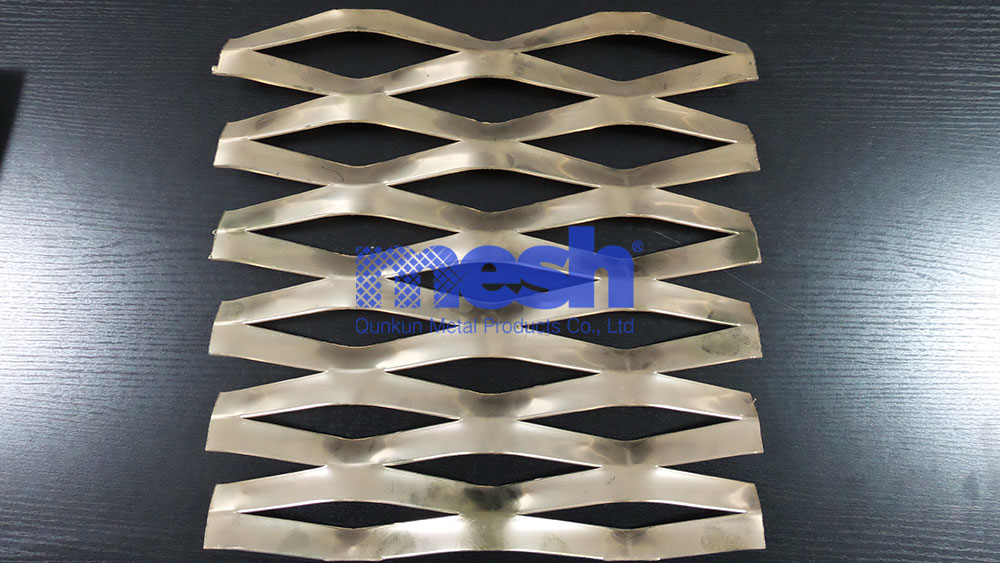

Coatings: A Variety of Protection Options

Coating is another common surface treatment method, and different types of coatings can be selected according to needs to achieve different protective effects. For example, coatings can provide additional corrosion resistance, UV protection and scratch resistance. For outdoor environments, choosing a coating with UV resistance and weather resistance can effectively extend the service life of Expanded Metal Mesh.

Regardless of the surface treatment chosen, proper maintenance is key to maintaining the protective effects of Expanded Metal Mesh. Regular cleaning, avoiding physical damage, and regularly checking the condition of the coating or protective layer can help prolong the protective effect and ensure the beauty and durability of Expanded Metal Mesh. By understanding the different surface treatments of Expanded Metal Mesh, you can better Choose the protection method that suits your project needs.

-

Best Chain Link Fence for Security Applications Feb 10, 2026

Best Chain Link Fence for Security Applications Feb 10, 2026 Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China